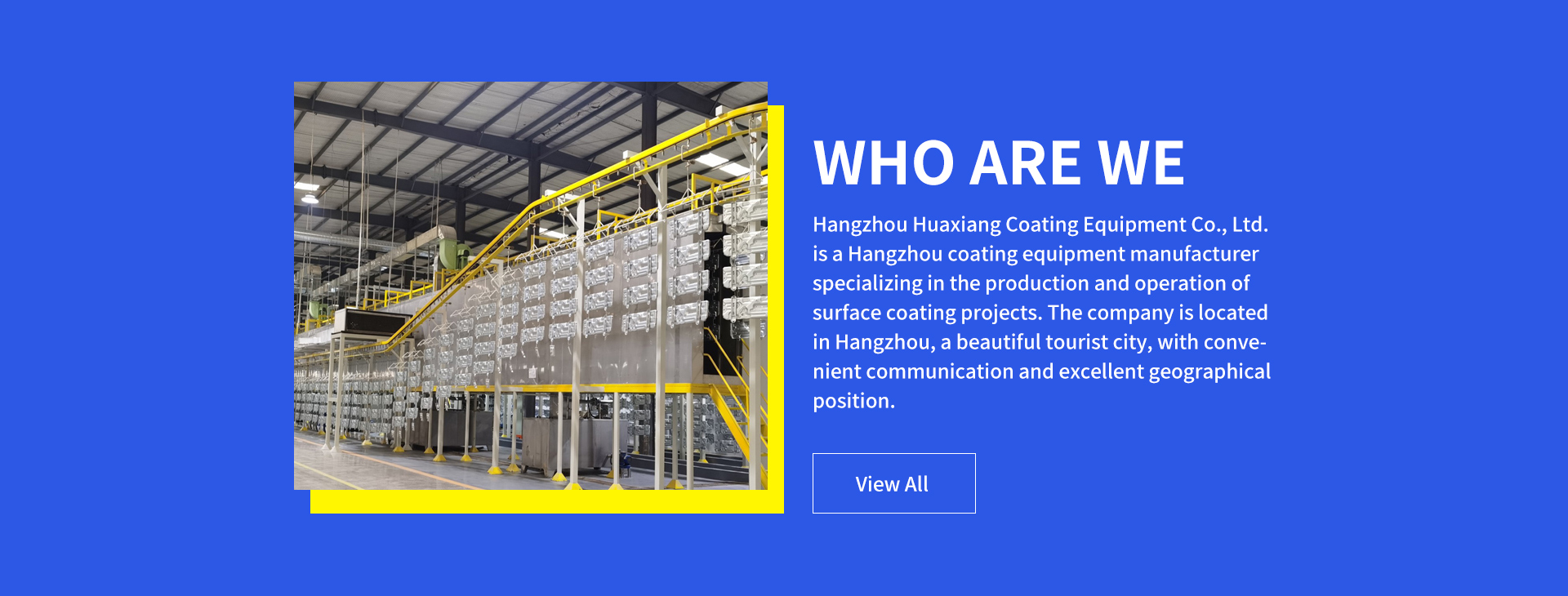

Powder Coating Lines have revolutionized surface finishing across industries by offering eco-friendly, durable, and cost-effective solutions. Unlike traditional liquid coatings, powder coating eliminates solvents, reducing VOC emissions and waste. The process involves electrostatically applying dry powder to a substrate, which is then cured under heat to form a resilient, uniform layer. Modern powder coating line systems are versatile, catering to metals, plastics, and composites, and are widely used in automotive, aerospace, furniture, and architectural sectors. Their efficiency, low environmental impact, and superior finish quality make them indispensable in industrial manufacturing.

1. Introduction to Powder Coating Line and Equipment Components

A Powder Coating Line comprises several integrated components. The primary equipment includes a pretreatment system (cleaning and phosphating), drying oven, electrostatic spray booth, powder recovery unit, curing oven, and conveyor system. The pretreatment stage ensures surface cleanliness for optimal adhesion. Electrostatic spray guns apply charged powder particles evenly, while recovery units recycle overspray, minimizing waste. Curing ovens polymerize the powder at controlled temperatures. Conveyors transport parts seamlessly through each stage, ensuring efficiency. Advanced systems may incorporate automated controls for precision and scalability.

2. Applications of Powder Coating Line in Industry

Powder Coating Lines are essential in industries requiring high-quality finishes. Automotive manufacturers use them for wheels, chassis, and engine parts. Architectural firms apply powder coating to aluminum windows, railings, and facades for weather resistance. Home appliances like refrigerators and washing machines benefit from scratch-resistant surfaces. Additionally, aerospace and agricultural equipment sectors rely on powder coating lines for corrosion protection and aesthetic appeal. Their adaptability to complex geometries and diverse materials drives widespread adoption.

3. Design Considerations for Powder Coating Line Systems

Designing a Powder Coating Line demands attention to workflow, energy efficiency, and safety. Layouts must optimize space for pretreatment, spraying, and curing zones. Proper airflow in spray booths prevents powder accumulation, while efficient oven insulation reduces energy consumption. Fire-resistant materials and explosion-proof systems are critical for safety. Additionally, compatibility with part sizes and production volumes ensures scalability. Integrating IoT-enabled monitoring tools enhances process control and maintenance.

4. How to Choose the Right Powder Coating Line

Selecting a Powder Coating Line depends on production needs, material types, and budget. For small batches, manual or semi-automatic systems suffice, while high-volume manufacturers require fully automated lines. Evaluate powder recovery rates (ideally above 95%) and curing oven temperature ranges (typically 150°C–200°C). Consider suppliers offering after-sales support and modular upgrades. Energy-efficient models lower long-term costs, and compliance with ISO or OSHA standards ensures reliability.

5. Q&A on Powder Coating Line Equipment

Q: What pretreatment is needed for a powder coating line?

A: Degreasing, rinsing, and phosphating are vital to remove contaminants and enhance adhesion.

Q: Can powder coating lines handle heat-sensitive materials?

A: Yes, low-temperature cure powders (120°C–140°C) are available for plastics or thin metals.

Q: How to maintain powder coating equipment?

A: Regular cleaning of spray guns, filter checks, and oven calibration ensure consistent performance.

Q: What safety measures prevent fire risks?

A: Install spark detection systems, ground equipment to avoid static, and use explosion-proof lighting.

Q: Is powder coating cost-effective for small businesses?

A: Compact, benchtop powder coating systems offer affordable entry points with minimal waste.

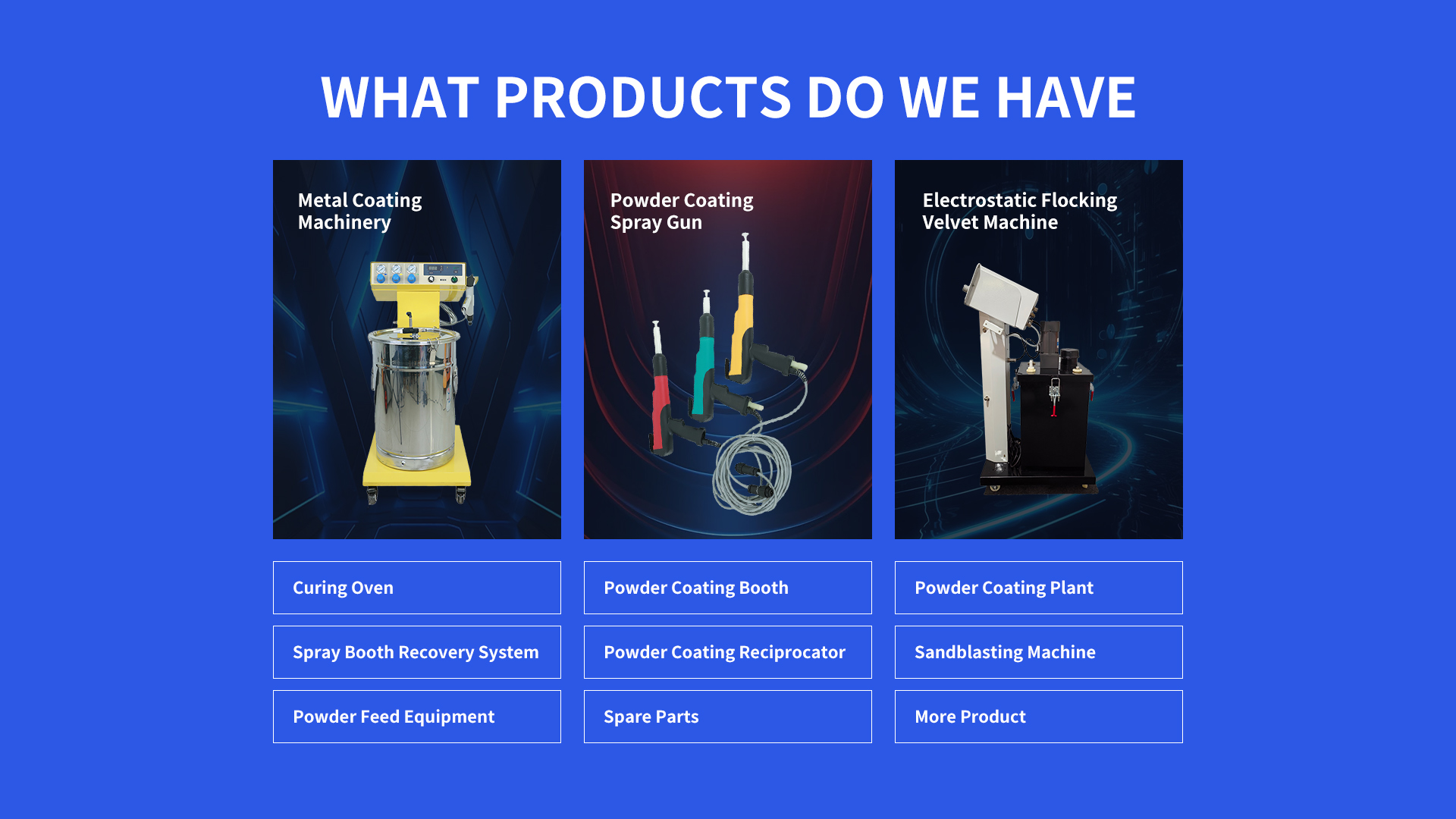

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com